|

Toshiba TOSVERT VF-AS1 |

|

|

|

High Precision -

Unsurpassed

Performance

The VF-AS1 is an advanced inverter drive for the most demanding, high end

industrial machine and equipment applications. It performs high

torque, quick response, high accuracy and excellent environmental

capability. The VF-AS1 designed

to operate under extreme environments,

delivering high precision controls. Yet the VF-AS1 is easy to

operate with "my function". |

|

|

Power Capacity |

|

|

|

Key Features |

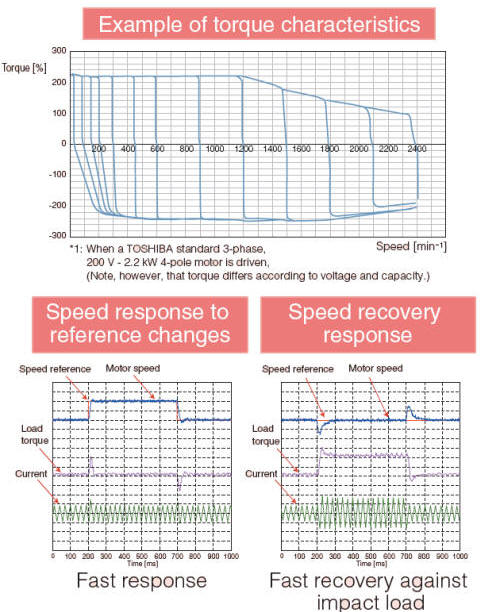

- The VF-AS1

offers (both sensorless and feedback) vector control

providing heavy duty, powerful performance with high

precision control. On drives provided with a sensor,

high-torque operation of 200%* from zero velocity is

possible, achieving a speed control range of 1:1000.

Using the new Motor-Over-Flux-Braking-Technology, the

AS1 can provide as much as 30% of its rated power for

use in stopping a heavy or high inertia load without the

use of a dynamic brake resistor.

Motor constants required for vector control can also be

easily set by auto-tuning to achieve 1:120 speed

control. The VF-AS1 features a robust structure that

reduces the negative effects and influence of motor

temperature.

|

|

- High-speed

response frequencies of 40 Hz without sensor and 50 Hz

with sensor to maintain fixed speed in response to

sudden changes in load. Modifying software enables

high-frequency output up to 1000Hz, which is ideal for

spindle rotation of woodworking and metalworking

machinery.

|

|

-

Toshiba’s "My Function" programming set

allows the VF-AS1 to operate as a simple PLC. Basic

logic function programming can now be done directly on

the VF-AS1.

-

High-frequency noise is drastically

reduced on models with built-in noise filters. Built-in

noise filters are ideal for sites such as commercial

facilities, offices and factories where attention must

be paid to peripheral devices. Models with built-in EMC

noise filter comply with the European EMC Directive as

individual inverter units. Savings in space and wiring

have been achieved by incorporating the filter in the

panel.

|

|

|

- The

VF-AS1 drive is designed to operate under extreme

environments. It can operate in temperatures up to 122°F

without de-rating and can be configured for use in

temperatures of up to 140°F. The VF-AS1 is also designed

to be used in a sealed cabinet design which allows

integrators to mount the VF-AS1's heat-sink external to

the drive cabinet for simple and efficient cooling of

the unit.

|

|

-

The modular

construction of the VF-AS1 allows the unit to be

installed into nearly any application quickly and

easily. The laminated bus plane technology used in the

VF-AS1 means a reduced component count, better

reliability and easier service.

The removable control

terminal board allows you to use the control wiring when

replacing the inverter, which makes maintenance easier.

|

|

|

|

Removable Control

Terminal Board |

|

|

- Dedicated advanced

functions and features for lifting/holstering

applications are

implemented in the VF-AS1. The brake sequence function

measures the timing with braking by an external motor to

achieve smooth operation at start and stop of braking

operation. The light-load, high-speed function

automatically increases the speed when operating light

loads according to the lifting load to improve

conveyance efficiency. A learning function for setting

and storing to memory required parameters while

performing actual operations is also provided to

facilitate adjustments. The VF-AS1's built-in transistor

used for dynamic braking is rated up to 160 kW.

|

|

-

Based on Toshiba’s unified

programming philosophy, the VF-AS1 can be operated with

little or no programming. At the same time, the AS1

maintains one of the most expansive parameter sets in

the industry, allowing you to fine tune the drive for

your specific application.

-

Issues with your

application will no longer be a mystery with VF-AS1's

fault tracing algorithm. By accessing the fault tracing

parameters, you can isolate exactly where the trouble is

located

|

|

|

-

The AS1 is designed to

accommodate multiple, stackable option cards that can be

mounted underneath the unit’s keypad quickly and easily.

The drive can accept two inputs from external

communication units via the two onboard RS 485

communication ports.

|

|

-

Compliance with global

standards including CE, CSA, UL, C-tick, GOST, NOM117

|

|

|

|

Application Notes |

- Offset Printing Machine

- Metal Working Machine -

Winders

- Semiconductor

Manufacturing Equipment - Chip Cutters

- Hoisting Equipment -

Overhead Travelling Crane

|

|

|

Catalogues & Manuals |

|

|

Catalogues: (Select language) |

|

|

|

Manuals: (Select language) |

|

|

|