|

Toshiba TOSVERT VF-AS3 |

|

|

|

IoT / Industry 4.0 Ready-

High Performance Inverter

The AS3 is Toshiba’s latest high performance inverter drive featuring state-of-the-art motor control technology and enhanced communication. With built-in Ethernet communication, the AS3 meets all the requirements of modern automation systems for evolution of Internet of Things (IoT) / Industry 4.0. Powered by dedicated high speed processor and network communications, users can easily access and monitor real-time data for analysis and processing to maximize system performance. |

|

|

Power Capacity |

|

|

- 150% for 60 seconds (at HD Heavy Duty Rating)

- 120% for 60 seconds (at ND Normal Duty Rating)

|

|

|

Key Features |

|

- The VF-AS3 has embedded dual Ethernet port for real-time communication. Therefore the VF-AS3 can be directly integrated into various IoT or plant & process control systems through connection to network or internet.

- With the AS3's built-in web server, the drive's status and operting conditions information can be easily accessed from a standard web browser. With network communications the AS3 can be monitored and controlled remotely from a PC, smartphone, or tablet devices.

|

|

|

- The AS3's operating panel can be detached from the drive and mounted remotely on external control consoles, cabinet doors etc.

- Operating panel with touch wheel control prevents dust and water penetration. IP65 rated mounting kit also available.

- Wide, multi-language LCD display with detailed decription of parameters. Backlight turns red to easily recognize fault condition.

|

|

|

|

Detachable LCD Operating Panel |

|

|

|

- In the event of drive fault, VF-AS3

displays the QR Code®, which will provide immediate access to website for support and maintenance. Video guidance is available for installation, setup and maintenance

|

|

|

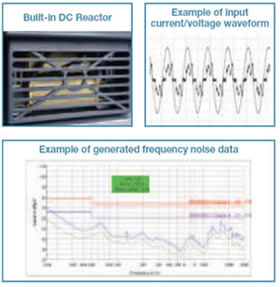

- Built-in DC Link reactor suppresses harmonic current and improves power factor, compliant with IEC61000-3 harmonic standards without external filter.

- Built-in EMC filter suppresses high frequency noise to prevent interference affecting sensitive peripheral devices. The AS3 complies with EMC directive IEC61800-3 Category C2/C3.

- Enhanced environment resistance - The AS3 can be operated at ambient temperature from -15 to 60°C. The lifetime of fans and electrolytic capacitors used in AS3 are designed be over 10 years.

|

|

- Single coltroller architecture and dedicated Ethernet processor provides high speed response

- Integrated "My Function" for logic type PLC programming with extended logic functions, arithmetic operations and program steps.

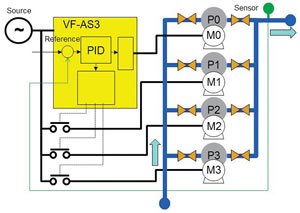

- VF-AS3 has four independent PID controllers built-in: two for drives (motors) and other two for external

devices such as heaters and valves.

- Function sensor feedback for rotary encoders or resolvers. Built-in position control with Point to Point, Pulse input and

Orientation control

|

|

Detachable Control Terminal Block |

|

|

- Embedded real-time clock for scheduled operation and fault/trip logging. Users can create a schedule for certain operations to be performed using AS3's calendar function.

|

|

|

- The calendar function includes following settings:

- Present time setting: Year, Month, Date, Hour, Minute

- Time adjustment through network communication

- Time zone with daylight saving time

- 4 start time and 4 stop time

- Holiday setting

|

|

| Multi Pump Control - For Water/Wastewater Pump Systems |

- Multi pump control for maximum 10 pumps with pump control sequence setting. The multi-pump control scheme not only saves energy and cost, but also reduces downtime

- The PID functions include temperature or pressure control of fan and pump, speed control of

a winder, stop position control, etc.

- With calendar function, pump motor operation time can be scheduled and equally shared across multiple pumps

|

|

| Multi pump control |

|

|

| IoT Systems Solution - For Plant & Process Control Application |

- The AS3 can be connected with various devices through local area network, wireless network, and the Internet.

- Real-time data (such as power, operating frequency etc...) collected from the AS3 through network communication can be analyzed to optimize system efficiency

- The sensors and devices

connected to the AS3 can also be monitored through network communication.

- The AS3 This IoT-Ready function increase productivity and reduce total cost.

|

|

|

| High Performance Motor Control and Safety - For Conveyor / Crane systems |

- The starting torque with sensor-less vector control is 200% with 0.3Hz or more. The AS3

achieves high starting torque and high accuracy regenerative torque at low frequency.

- PM motor drive with sensor vector control for 200% torque at zero velocity, speed control range of 1:1500, and high speed response frequencies of 100Hz.

|

|

|

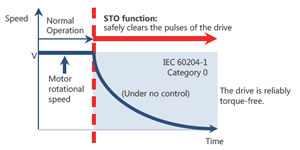

- STO (Safe Torque Off) as standard function

to cut off output in an emergency.

The STO function brings the machine safely into a no-torque

state and prevents it from starting accidentally.

Complies with safety standard IEC 61800-5-2 and also

achieves SIL3 level in IEC 61508 : 2010.

|

|

|

- Compliance with global

standards including CE, CSA , UL and TUV.

- Compliance with the European RoHS Directive.

|

|

|

|

Catalogues & Manuals |

|

|

Catalogues: (Select language) |

|

|

|

Manuals: (Select language) |

|

|

|